Introduction

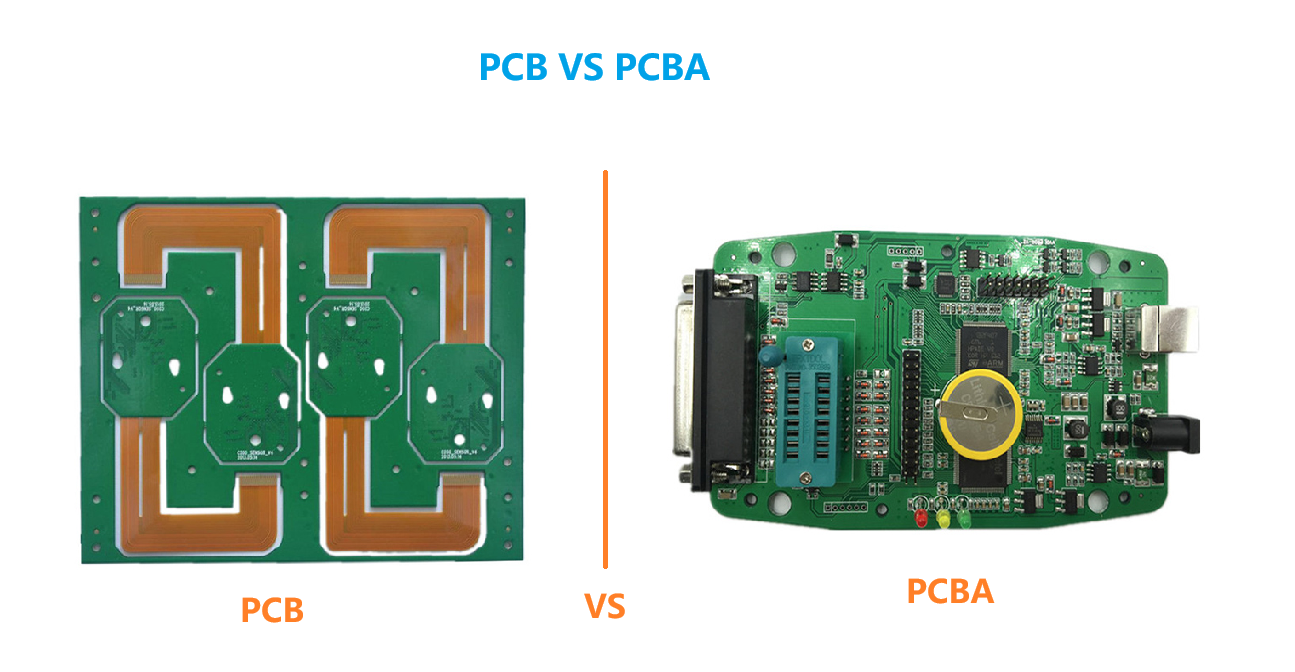

If you’re new to electronics manufacturing, the terms PCBA vs PCB might seem interchangeable—but they represent fundamentally different stages of production. Understanding their differences is critical when sourcing components or selecting a manufacturing partner.

In this guide, we’ll break down:

-

- Definitions of PCBA vs PCB

-

-

- Key structural and functional differences

-

- Step-by-step manufacturing processes

-

- How to choose the right solution for your project

1. What Is a PCB?

A Printed Circuit Board (PCB) is the bare, unpopulated board that forms the physical foundation of an electronic circuit.

Key Characteristics:

Base Material: Typically FR-4 fiberglass with copper layers

Components: No electronic parts attached (only conductive traces/pads)

Function: Provides mechanical support and electrical connections

PCB Manufacturing Process:

-

- Design & Gerber File Preparation

-

-

- Copper Cladding & Etching

-

- Drilling & Plating Through-Holes

-

- Solder Mask & Silkscreen Application

-

- Surface Finish (ENIG, HASL, etc.)

-

- Electrical Testing & Inspection

2. What Is a PCBA?

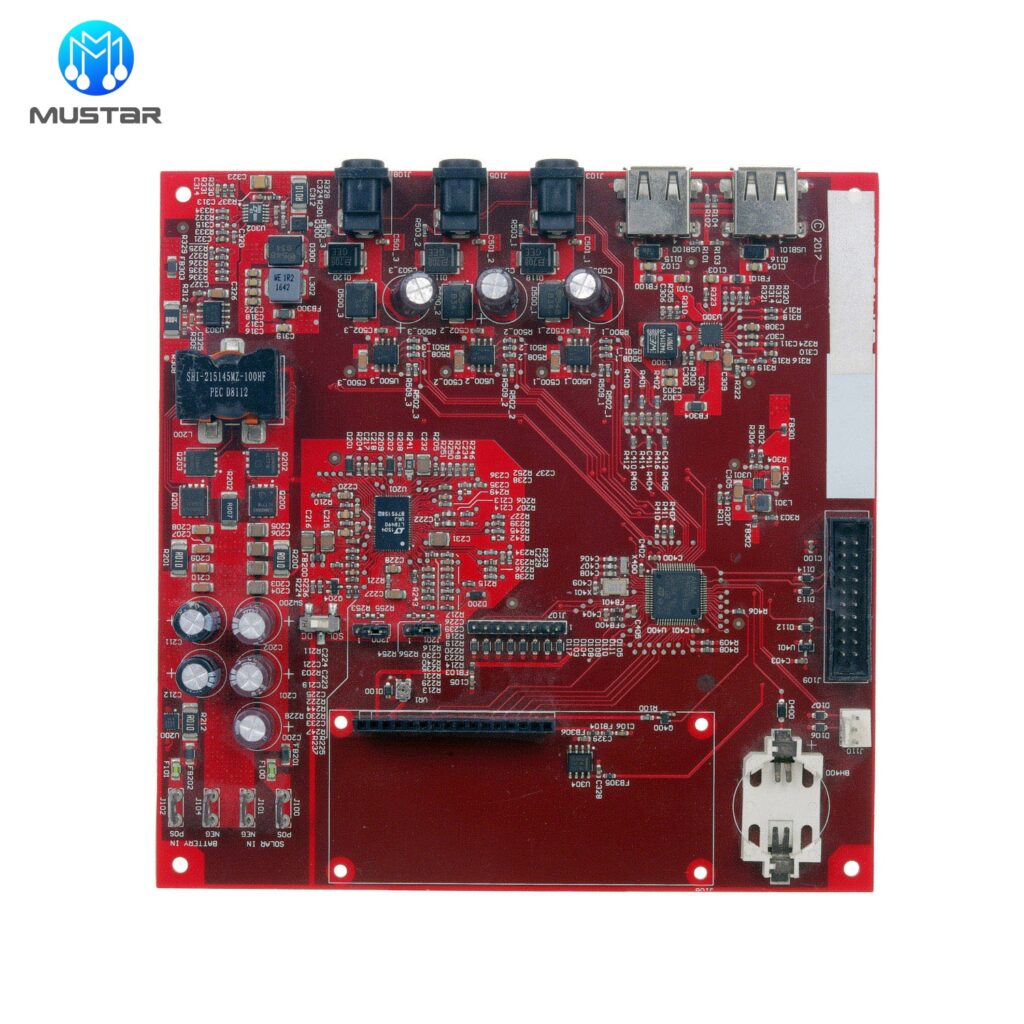

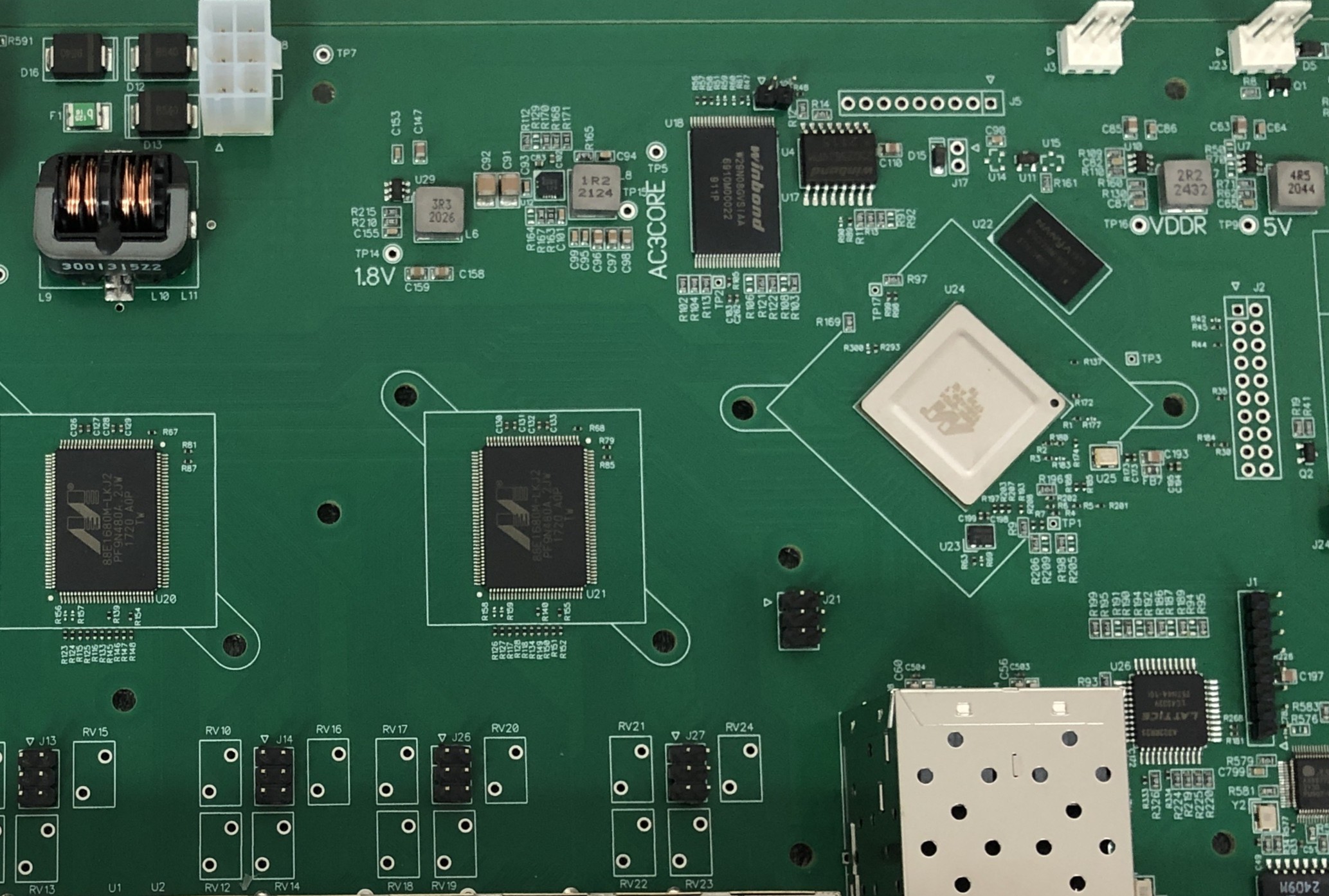

A Printed Circuit Board Assembly (PCBA) refers to a PCB that has completed the assembly process with all electronic components soldered onto it.

Key Characteristics:

Active Elements: Includes ICs, resistors, capacitors, connectors, etc.

Functionality: Ready for integration into end products

Test Requirements: Requires functional testing (FCT, ICT)

PCBA Manufacturing Process:

-

- Solder Paste Application (Stencil Printing)

-

-

- Pick-and-Place Machine Component Mounting

-

- Reflow Soldering (for SMT components)

-

- Through-Hole Component Insertion & Wave Soldering

-

- Cleaning & Conformal Coating (if needed)

-

- Functional Testing & Quality Control

3. PCBA vs PCB: Critical Differences

| Factor | PCB | PCBA |

| Components | Bare board only | Fully populated with parts |

| Functionality | Non-functional | Operational |

| Testing | Continuity/visual checks | Functional/performance testing |

| Lead Time | 3–5 days (typical) | 1–3 weeks (depends on complexity) |

| Cost Drivers | Layer count, materials | Component sourcing, labor |

4. Which One Do You Need PCBA vs PCB?

Choose PCB If:

-

- You’re a designer validating board layout

-

-

- You need prototypes before final assembly

-

- Components will be hand-soldered later

Choose PCBA If:

-

- You require a turnkey solution

-

-

- Your product is ready for mass production

-

- You lack in-house assembly capabilities

Pro Tip: Many OEMs (like us) offer free DFM analysis to optimize designs before PCBA production.

5. Why Partner With a Professional PCBA vs PCB Manufacturer?

-

- Avoid tombstoning, cold joints, or misaligned parts with expert SMT processes

-

-

- Reduce BOM costs through vetted component sourcing

-

- Accelerate time-to-market with rapid prototyping services

Conclusion

While PCBs are the starting point, PCBA transforms them into functional electronics. Whether you need bare boards or full assembly, selecting the right manufacturing partner ensures quality, efficiency, and scalability.

Need a quote or design review? Contact our team for a free PCBA feasibility analysis today.