In the highly competitive electronics industry, product longevity serves as a silent yet powerful sales tool. It strengthens brand reputation, fosters customer loyalty, and enhances overall product value. While designers skillfully select components and develop sophisticated circuits, potential failures can still hide within every new Printed Circuit Board Assembly (PCBA). So how can we uncover these hidden flaws and deliver on the promise of a 30% longer product lifespan? The answer lies in a critical, though often overlooked, manufacturing phase: PCBA aging tests, also commonly referred to as “burn-in” testing. Behind every reliable electronic product lies rigorous aging testing—a non-negotiable step in ensuring quality and durability.

This process goes beyond defect detection—it represents a strategic investment that can proactively extend your product’s operational life by 30% or more. Let’s explore how.

What is a PCBA Aging Test?

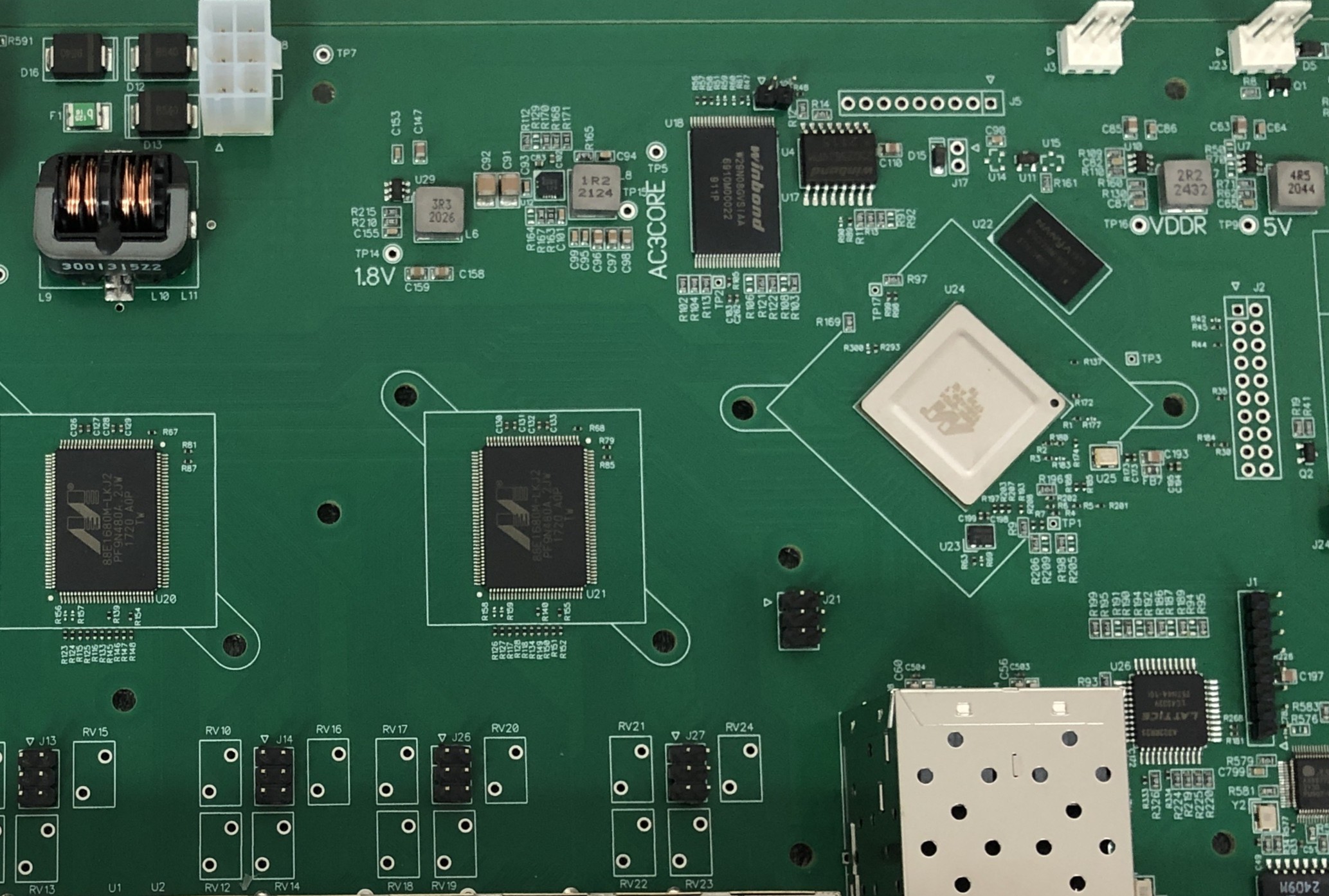

A PCBA aging test simulates weeks, months, or even years of operation within a condensed period—typically ranging from 24 to 168 hours. The assembly is powered on and placed in a specialized environmental chamber where it is exposed to elevated temperatures (often between 50°C and 70°C) and occasionally varying humidity levels. During this process, a dedicated “aging” software program runs to exercise all the board’s functions.

In essence, PCBA aging tests evaluate the performance and stability of electronic components under controlled environmental conditions over an extended period. The objective is clear: accelerate the failure of vulnerable components and expose latent defects before the product reaches the customer.

Why Perform PCBA Aging Tests?

The performance and stability of electronic components are crucial to ensuring product quality. However, factors such as prolonged operation and environmental stress can lead to performance degradation or failure. PCBA aging tests simulate real-world operating conditions to assess how components behave over time, helping to identify and eliminate potential issues before they affect the end user.

By conducting these tests, manufacturers can detect hidden defects, improve product reliability, and prevent premature field failures—ultimately ensuring higher customer satisfaction and reduced warranty claims.

How is PCBA Aging Testing Conducted?

A typical PCBA aging test involves the following steps:

Define Test Conditions: Set appropriate environmental parameters—such as temperature, humidity, and voltage—based on the product’s intended use case.

Apply Operational Load: Run the board under realistic workload conditions to simulate actual operating scenarios.

Conduct Extended Operation: Keep the PCBA powered and operational for a prolonged duration, usually ranging from several dozen to hundreds of hours.

Monitor and Record Performance: Regularly measure and log key parameters such as voltage, current, and temperature to track performance over time.

Analyze Results: Evaluate the collected data to determine whether the components meet stability and reliability requirements.

How Aging Tests Extend Lifespan by 30%

The claimed 30% extension in product lifespan is not merely a marketing tactic—it’s a achievable outcome through rigorous aging testing. Here’s how:

Elimination of Early Failures: By identifying and weeding out units prone to early failure, the average lifespan of the entire product batch increases. For instance, if 5% of units would have failed within the first year, removing them from the population statistically raises the overall product lifespan.

Stress Conditioning: The aging process doesn’t just screen out bad components; it also stabilizes the good ones. Thermal and electrical stress helps settle internal structures—such as capacitor dielectrics—and encourages the outgassing of residues from soldering, thereby reducing future risks of corrosion or current leakage.

Systemic Issue Identification: Consistent failures of a particular component during aging can reveal broader supply chain or design issues. This insight allows engineers to address root causes—whether by switching suppliers or modifying designs—thereby enhancing the robustness of future production runs.

Solder Joint Reliability: Thermal cycling causes expansion and contraction, stressing solder joints mechanically. Weak joints with cracks or poor wetting are likely to fail during burn-in, allowing replacement at a fraction of the cost of a field failure.

Viewing aging tests as an investment in quality shifts the cost-benefit perspective. The upfront expense is minimal compared to the savings from avoided returns, repairs, and the preserved reputation of your brand.

Conclusion: Don’t Leave Product Longevity to Chance

PCBA aging testing is essential for ensuring the reliability and stability of electronic products. Through carefully designed test conditions, realistic operational loads, extended operation, and meticulous performance monitoring, manufacturers can effectively uncover hidden defects and mitigate potential failures.

In the pursuit of durable products, design is only half the equation. Manufacturing validation—where theory meets reality—is what ultimately determines real-world performance. PCBA aging tests offer a proven method to eliminate early failures, enhance product conditioning, and fulfill the commitment to quality that customers expect.

By integrating aging tests into your production process, you’re not just testing products—you’re designing longer, more reliable lifespans for them. It’s proof that a few days inside a test chamber can add years to a product’s life.

Ready to build products that last? Contact us today to learn how our aging test solutions can be integrated into your manufacturing workflow