Mainly for over 4 layers precision board, production capacity up to 64 layers

Special base material: Teflon, High-Tg, Rogers, Ceramics(R-1566WN, F4BTMS220, RT Duroid 5880, Megtron6)

Technology: Buried via, Blind via, Back drill, impedance control

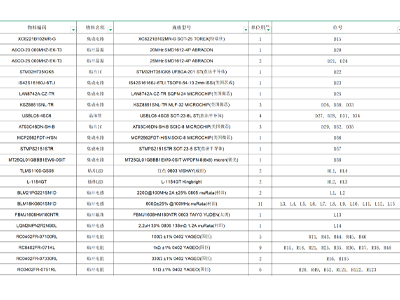

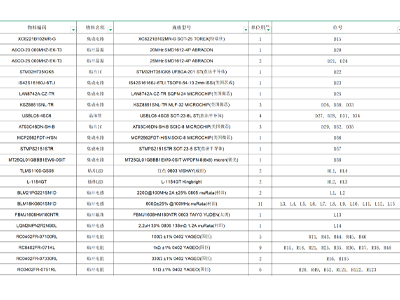

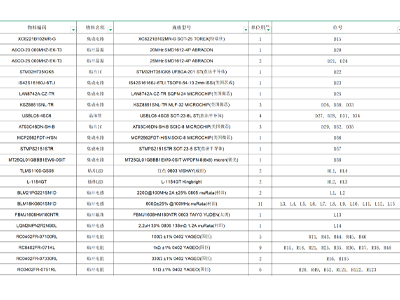

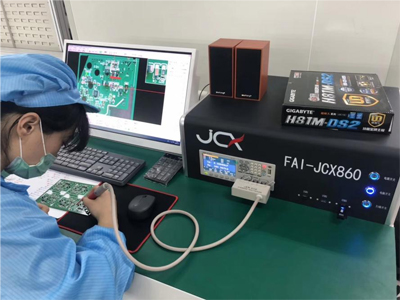

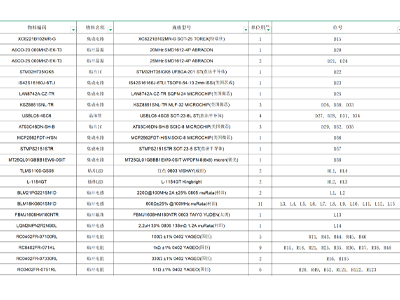

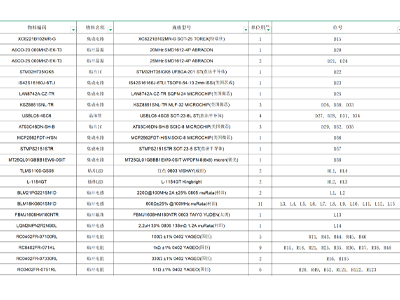

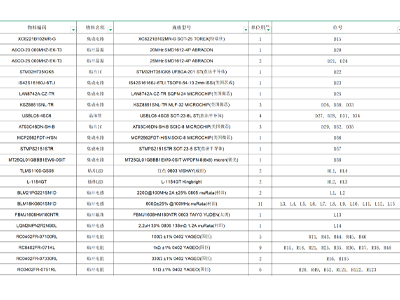

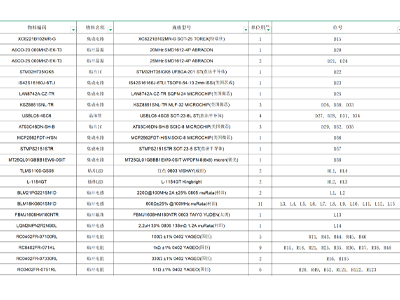

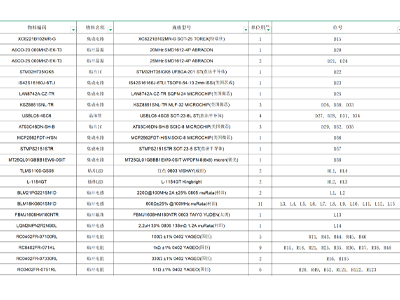

100% match customer’s BOM list, alternative can be recommend to save cost if customer degree Strict Incoming Material Inspection Temperature and humidity sensitive components storage room 24-hours fast delivery

Surface mount package capacity: 01005, BGA, QFN, DIP, SOP, QFP, PGA, BGA, CSP Complete Quality Control Process: X-ray, AOI, FAI, passed UL, 94v-0, CE, SGS, FCC, RoHS, ISO9001, ISO14001, ISO13485, TS16949 Certifications Special 8 SMT lines for high-precision Medical, Automotive, Industrial control board Standardized Operation Process: ERP System

Gather all required components (PCBs, ICs, resistors, capacitors, etc.) and verify their specifications before assembly, 100% match customer’s requirement.

Pre-bake moisture-sensitive components (MSDs) at controlled temperatures (typically 125°C for 8-24 hours) to prevent delamination or popcorn effect during high-temperature soldering.

Engrave serial numbers, barcodes, or logos on PCBs for traceability and identification.

Place PCBs onto the production conveyor to begin the automated assembly process.

Gather all required components (PCBs, ICs, resistors, capacitors, etc.) and verify their specifications before assembly, 100% match customer’s requirement.

Check for proper solder paste deposition (volume, alignment) to prevent soldering defects.

Use pick-and-place machines to mount small surface-mount (SMD) components (e.g., resistors, capacitors) at high speed.

Place larger or irregularly shaped SMD components (e.g., connectors, BGAs) that require precise handling.

Scan for missing, misaligned, or defective components before soldering.

Melt solder paste in a controlled oven to permanently attach SMD components to the PCB.

Inspect solder joints and component placement after reflow to catch defects like bridging or tombstoning.

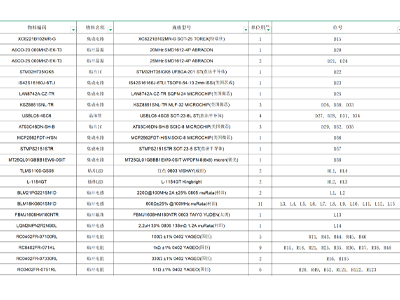

Perform comprehensive verification (dimensional, electrical, visual) on the initial production unit against engineering specifications before full batch release.

Insert through-hole components (e.g., connectors, large capacitors) manually or via machines.

Verify correct placement of through-hole components before wave soldering.

Solder through-hole components by passing the PCB over a molten solder wave.

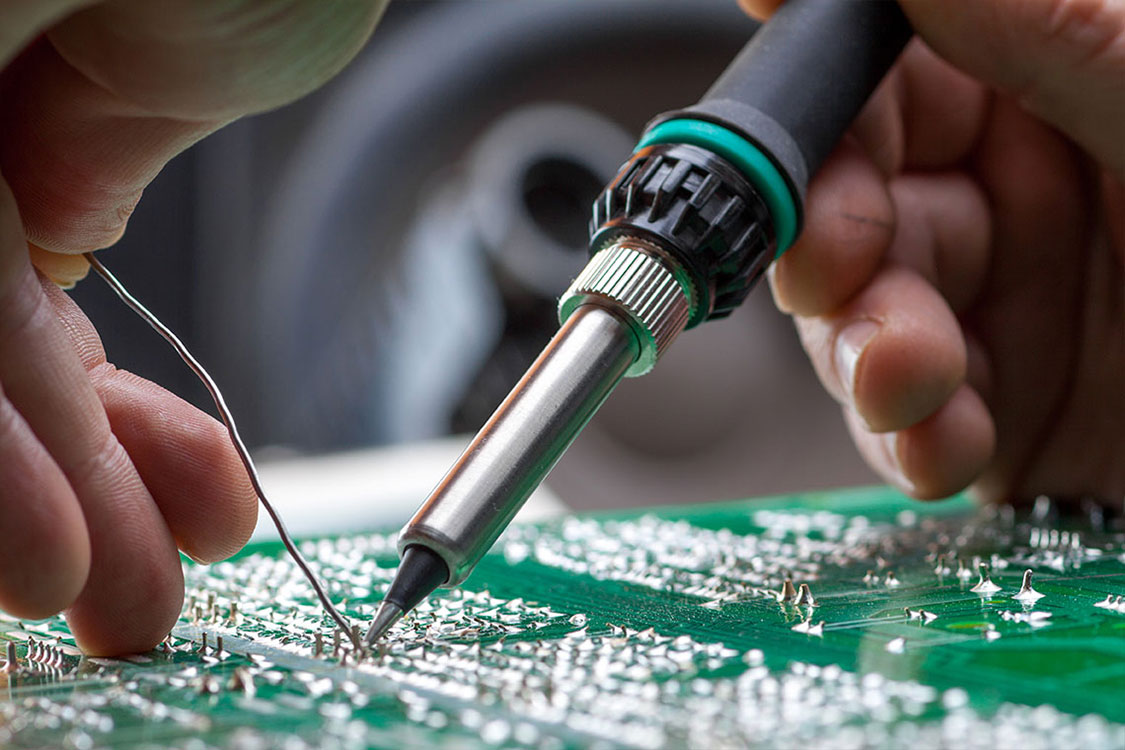

Manually repair poor solder joints (e.g., cold solder, bridges) after wave soldering.

Hand-solder components that cannot withstand high-temperature processes (e.g., heat-sensitive parts)

Conduct a comprehensive inspection to ensure all components and solder joints meet quality standards.

Perform functional tests (e.g., power-on, signal checks) to validate the board’s performance.

Apply a protective layer (e.g., silicone, acrylic) to prevent corrosion, moisture, and dust damage.

21.Integrate the PCBA into the final product (e.g., housing, connectors, displays)

Securely pack finished products with anti-static and shock-absorbing materials.

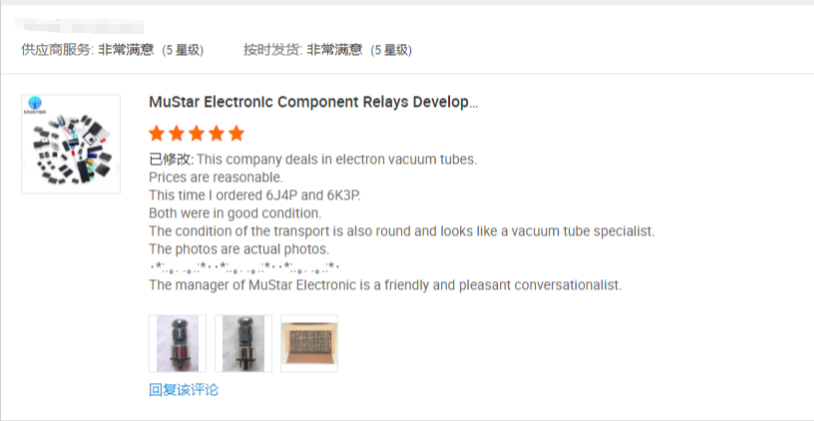

Founded in 1998 by Karma, MU STAR is proud to be ranked among the top 10 PCBA manufacturers in China. With over 25 years of experience, we have built a global footprint, exporting to 98+ countries and serving leading enterprises—including Germany Telecom (Deutsche Telekom) since 2016.

To date, we have successfully delivered 5,000+ electronic product projects, backed by a team of experienced engineers and certified production processes (ISO 9001, ISO 13485, IATF 16949, RoHS). Our services are especially tailored for Medical & Healthcare, Automotive Electronics, New Energy Systems, and Industrial Control sectors—where quality, stability, and speed are critical. With advanced facilities, strict quality control, and a client-first approach, MU STAR helps turn your electronic ideas into reliable, scalable products.

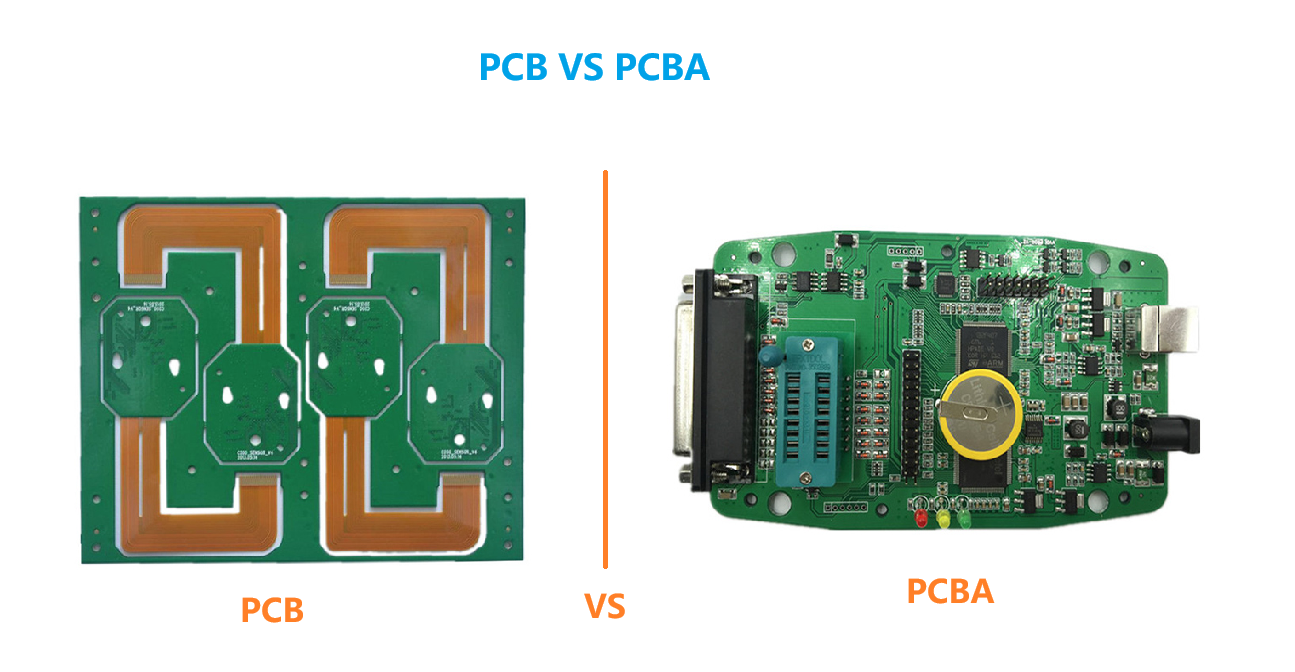

PCBA customized service by Mustar delivers end-to-end solutions from PCB fabrication to full assembly, tailored to your product requirements with speed and precision.

From PCB manufacturing to final assembly, we streamline the entire PCBA process under one roof.

Support for OEM/ODM projects with tailored design, components, and testing requirements.

Production meets ISO 9001, ISO 13485, IATF 16949, and RoHS standards for high reliability across industries.

Rapid prototyping and mass production with lead times optimized for your project needs.

Strong global supply chain to source original, cost-effective electronic components.

Experienced engineers assist in DFM, programming, and testing for complex or high-precision applications.

With over 25 years of expertise, Mustar is your trusted PCBA partner for high-quality, certified, and fully customized electronic manufacturing solutions. We combine technical strength, fast response, and strict quality control to deliver excellence in every board—whether for medical, automotive, new energy, or industrial applications. Partner with Mustar for peace of mind and production success.

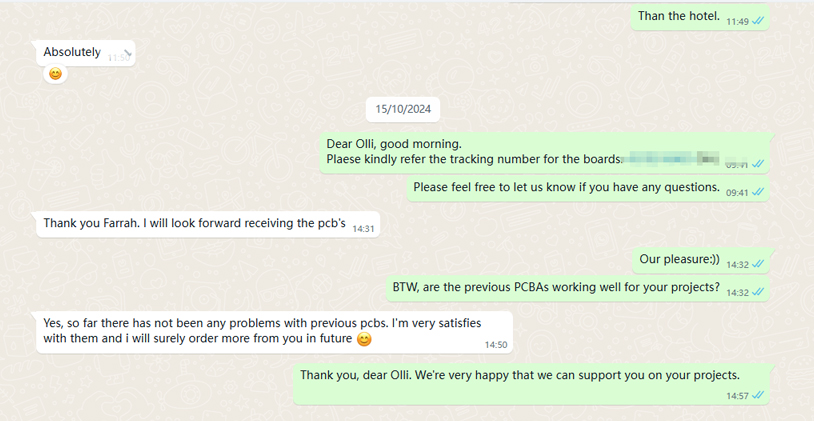

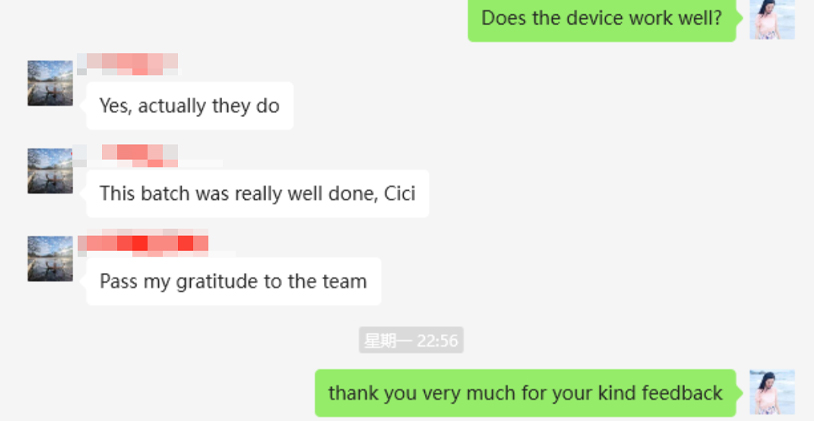

We partnered with Mustar for a new generation of our medical monitoring devices. From the initial DFM suggestions to the final batch testing, the team was proactive, highly responsive, and technically skilled. The assembled PCBs passed every compliance check in our EU lab. Most importantly, they met our tight 25-day timeline without compromising quality. Mustar truly acts as an extension of our in-house team.

Mustar has been our go-to PCBA supplier since 2019 for multiple vehicle control unit projects. They consistently deliver high-quality boards that meet our IATF 16949 and high-temp automotive specs. Their flexibility on low-MOQ sampling and speed of prototyping helped us accelerate product launches by 20%. With Mustar, we don’t just buy PCBA—we get dependable technical partnership.

Our IoT-based home automation startup needed a vendor who could handle full turnkey service, from layout review to firmware preloading. Mustar handled it all smoothly. Their engineering team helped us redesign a section of the PCB to improve signal stability, and their sourcing team even secured hard-to-find Wi-Fi modules during shortages. We’ve scaled up to 80,000+ units with zero major quality issues.

Upload your Gerber files, BOM list, assembly drawings, and any special process instructions.

Our engineering team will review your files and provide a detailed quotation with lead time.

Confirm the quotation and production details, sign the order, and complete the payment.

We proceed with PCB manufacturing, component sourcing, and assembly, followed by quality testing and on-time shipment.

cici@mustarpcba.com

+86 159 8076 8616

+86 159 8076 8616

#603, Building C, Qianwan Key & Core Technology Industrial Park, Bao'an District, Shenzhen China

Your submit is 100% safe & secure!

Reliable, fast, and precise PCBA manufacturing — from prototype to production.Let’s bring your product to life.

© 2023 Created with MSPCBA