Introduction

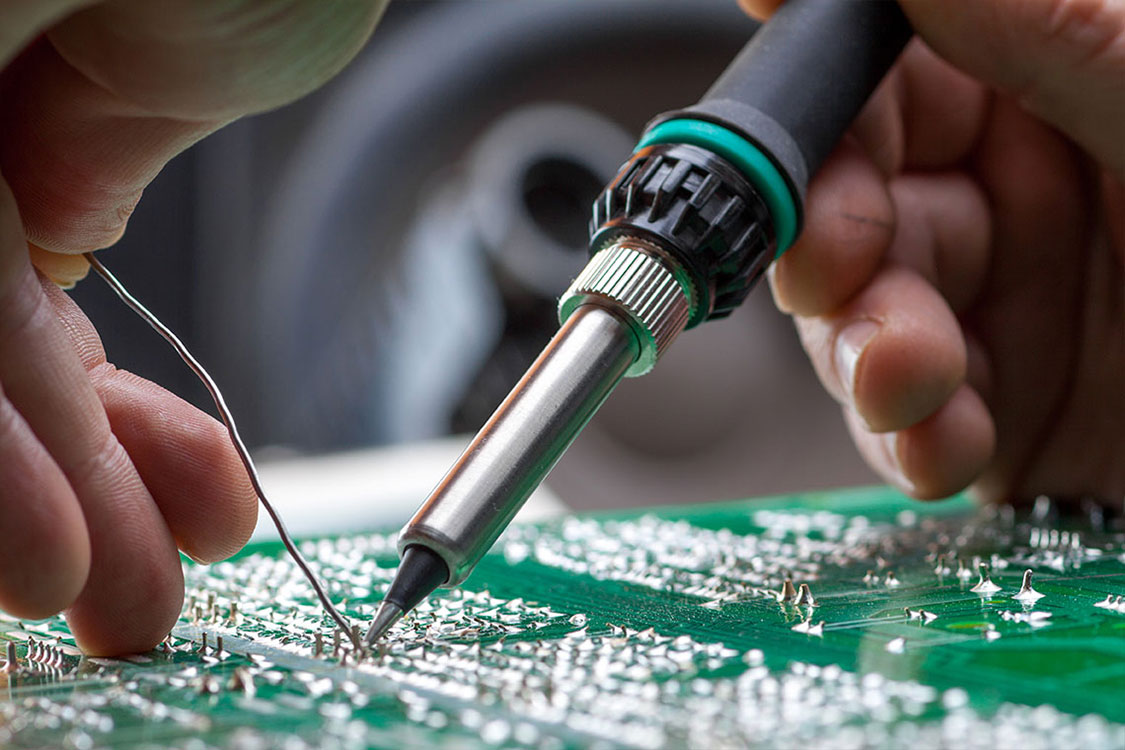

Soldering is the process of joining two metal structures with the help of a metal alloy. The alloy (also known as the solder) is heated to high temperatures with a handy tool called soldering iron, which causes the alloy to melt. The molten solder is applied to the metal joint, and once it solidifies, a strong bond is formed. let us discuss together “Lead-Free or Leaded Solder Paste? Key Differences and How to Choose”.

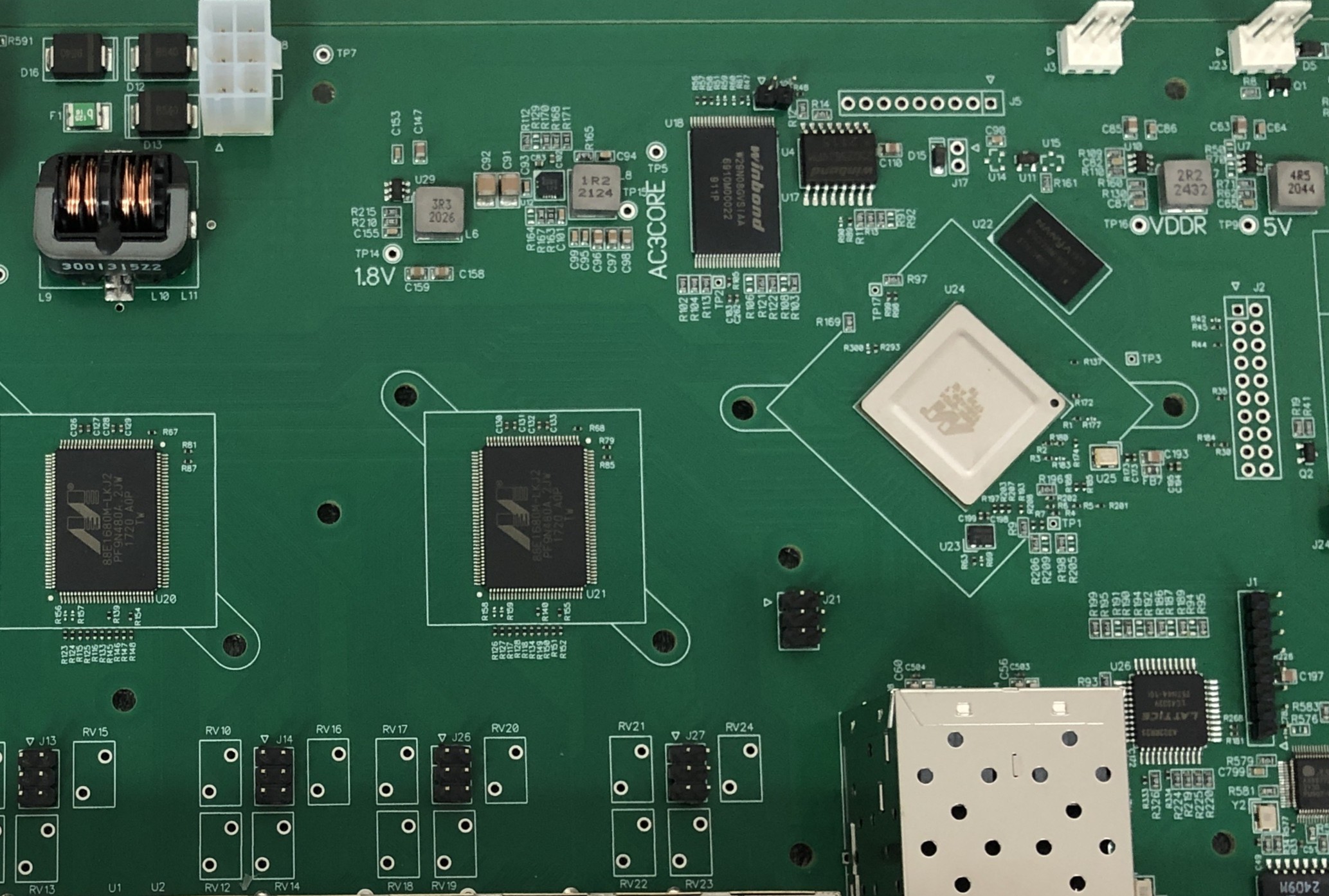

Solder joints are used in electronic manufacturing to connect various components such as resistors, capacitors, inductors, integrated circuits (ICs), and more on printed circuit boards (PCBs).

The soldering process differs from welding in the way that it doesn’t require the base metal to melt. The solder joint is much weaker but can be formed at a lower temperature than welding.

Solder Paste Selection Guide: Understanding Lead-Free vs. Leaded Options for Your Projects

When working on PCB assembly, one of the most critical decisions is choosing the right solder paste. The debate between lead-free and leaded solder paste is ongoing, with each type offering distinct advantages and drawbacks. Whether you’re a hobbyist, an electronics manufacturer, or an engineer, understanding the key differences between these two solder pastes will help you make an informed choice.

In this guide, we’ll compare lead-free vs. leaded solder paste in terms of melting temperature, mechanical strength, environmental impact, and industry compliance. By the end, you’ll know which type best suits your project requirements.

What’s the Difference Between Lead-Free and Leaded Solder Paste?

Composition & Melting Point

- Leaded solder paste typically contains tin (Sn) and lead (Pb), often in a 63/37 or 60/40 ratio. It has a lower melting point (~183°C for 63/37), making it easier to work with.

- Lead-free solder paste is made of tin, silver (Ag), and copper (Cu) (e.g., SAC305: 96.5% Sn, 3% Ag, 0.5% Cu). It requires a higher melting point (~217–227°C), which can affect thermal stress on components.

Wettability & Solder Joint Quality

- Leaded solder flows better, creating smoother joints with fewer defects like voids or cold joints.

- Lead-free solder can be less forgiving, sometimes requiring better flux formulations or nitrogen-assisted reflow to improve wetting.

Physical Features

It is sometimes possible to differentiate lead solders from others by just a visual inspection. Solders with lead content usually appear shinier than lead-free ones. The shininess of solders was typically associated with their quality.

Apart from the physical appearance, lead-based solders also perform a bit better compared to their lead-free alternatives in terms of electrical and mechanical characteristics. Engineers and hobbyists who have worked with lead-based solder sometimes don’t readily accept lead-free solder as the performance, reliability, and ease of use of the latter are inferior compared to the former.

However, it’s equally true that things have changed now; the lead-free solders have improved continuously and are almost at par with their lead-based counterparts today. Here is a table comparing the various physical properties of commonly used lead and lead-free solders:

| Item | Traditional lead eutectic Sn37Pb solder | Lead-free SAC387 solder | Lead-free Sn0.7Cu solder |

| Density (g/m2) | 8.5 | 3.5 | 3.31 |

| Melting Point (°C) | 183 | 217 | 227 |

| Resistivity (MΩ-cm) | 15 | 11 | 42278 |

| Electrical Conductivity (IACS) | 11.5 | 15.6 | NA |

| Coefficients of thermal expansions (CTE) (×10-4) | 23.9 | 23.5 | NA |

| Thermal Conductivity (W/m·1k·1s) | 50 | 73 | NA |

| Surface Tension 260°C (mN/m) | 481 | 548 | 491 |

| Fatigue Life | 3 | 1 | 2 |

| Shear Strength (MPa) | 23 | 27 | 20-23 |

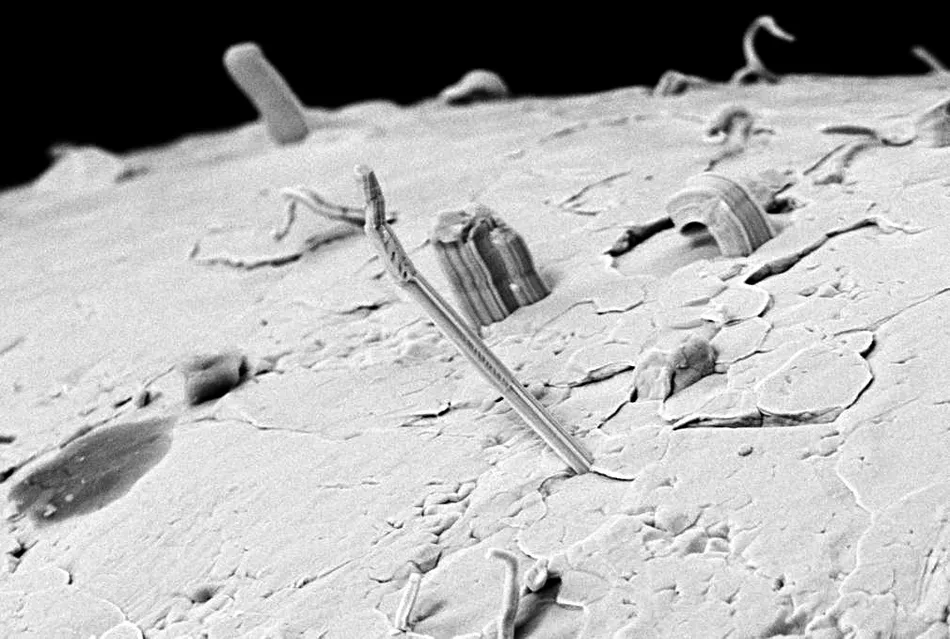

Tin Whiskers

Tin whiskers are microscopic thread-like structures that randomly emanate from pure tin surfaces and form electrically conductive paths. It is not yet known why or how they are formed, but they momentarily cause short circuits wherever they grow.

A large number of whiskers arise from pure tin; hence, it is mixed with some amount of other elements, such as lead to mitigate this phenomenon. The effect of tin whiskers is more severe in lead-free solders, which is why they have to be treated to improve reliability.

Health Concerns

Lead-free soldering is increasingly being embraced by environmentally-conscious companies due to the toxic nature of lead and its accumulation in the human body, even from small and prolonged exposures. Lead can easily enter the body through the skin, mouth, or nose and poses a greater risk to children and old persons. Although the paint and gasoline industries have successfully eliminated lead, solder is still one of the remaining products that use it. Workers in industries with high lead emissions are at greater risk of exposure and must take health concerns seriously.

However, taking these factors in mind the Waste Electrical and Electronic Equipment Directive and Restriction of Hazardous Substances Directive in the year 2006 restricted the use of lead in consumer electronics.

How to Choose the Right Solder Paste for Your Needs

When to Use Leaded Solder Paste:

- Prototyping & hobby projects (where RoHS compliance isn’t required)

- High-reliability applications (military, aerospace, or medical devices with exemptions)

- Repairing older electronics (compatible with legacy leaded solder joints)

When to Use Lead-Free Solder Paste:

- Commercial & consumer electronics (must comply with RoHS regulations)

- Mass production (required for international market sales)

- Environmental & workplace safety concerns (reduces toxic exposure)

Conclusion: Which Solder Paste Should You Use?

The choice between lead-free and leaded solder paste depends on your project requirements, industry regulations, and soldering conditions.

For manufacturers carrying out their development, manufacturing, sales, and operations in countries that have restricted the use of leaded electronics, there’s no choice but to use lead-free solders.

If options are available to choose between lead and lead-free solders, hobbyists may choose lead-based solders for small-scale applications, as lead solders are easy to work with and are cost-effective. But as far as commercial usage is concerned, lead-free solders are a sensible choice.

- Choose leaded solder if you need easier soldering, better joint quality, and aren’t restricted by environmental laws.

- Opt for lead-free solder if you’re manufacturing commercial products or prioritizing environmental safety.

By understanding these key differences, you can select the best solder paste for optimal performance and compliance.

Welcome to contact us to help you analyse your projects.