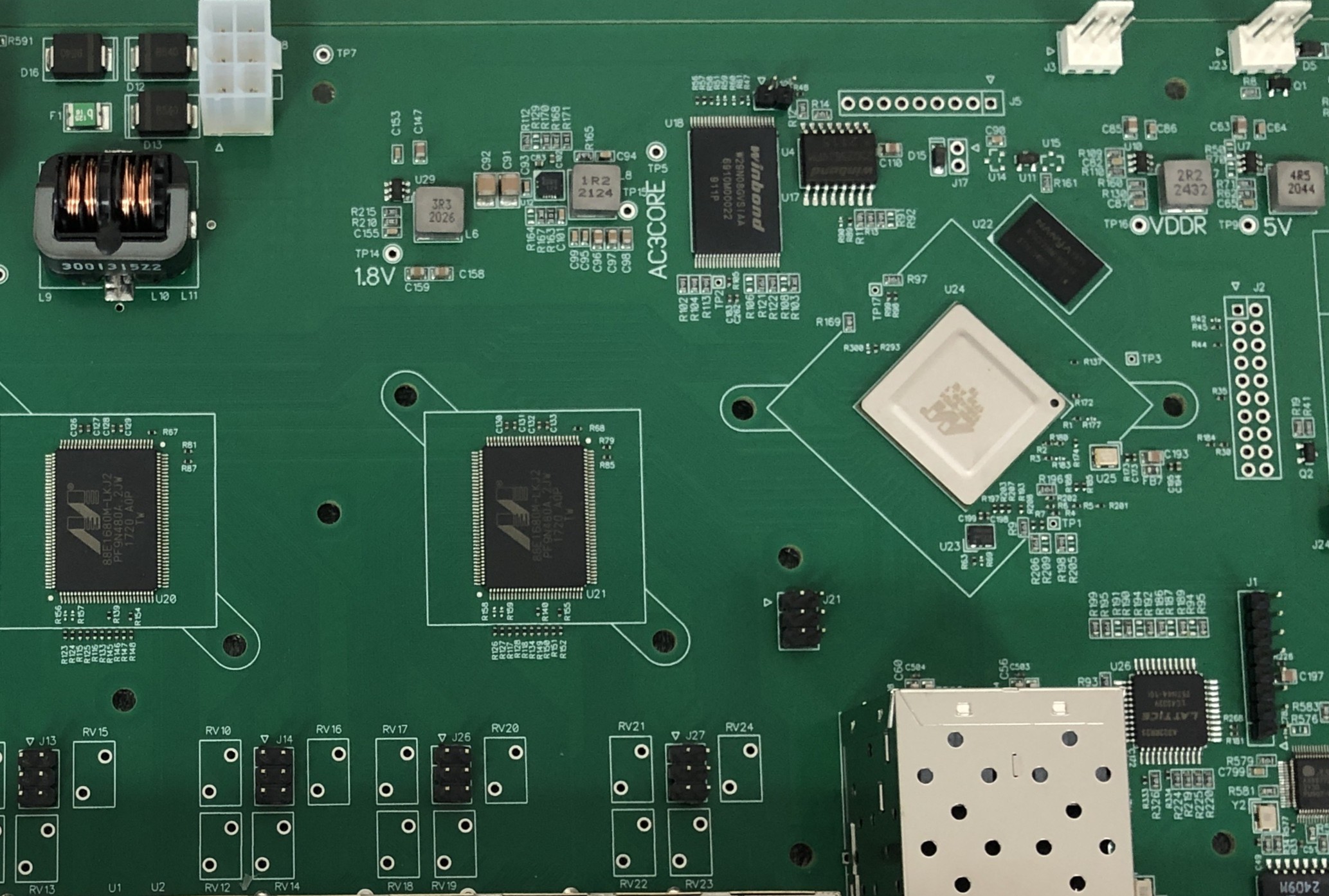

In the competitive world of electronics, managing production expenses is crucial for success. Whether you’re a startup or an established company, optimizing your PCBA (Printed Circuit Board Assembly) manufacturing costs without sacrificing quality is a key business strategy. Here are 10 practical ways to Guide you to Reducing PCBA Manufacturing Costs.

1. Optimize Board Size

Smaller boards generally cost less to manufacture. By reducing your board dimensions, you decrease material usage and increase the number of boards that can be panelized, leading to better material utilization and lower per-unit costs. However, ensure that component density remains manageable for assembly.

2. Reduce Layer Count

Each additional layer increases fabrication complexity and cost. While multilayer boards are necessary for complex designs, carefully evaluate if you can reduce layer count through better layout optimization. Often, creative routing and component placement can maintain functionality with fewer layers.

3. Select Appropriate PCB Base Materials

Not every project requires high-end PCB base materials. Choose substrate materials that meet your technical requirements without over-specifying. For many commercial applications, standard FR-4 is sufficient and much more cost-effective than specialized materials.

4. Use Standard Component Packages

Standard-sized components (like 0402, 0603, or 0805 packages) are typically more readily available and less expensive than custom or unusual (like BGA, QFN, or SOP packages) sizes. They’re also easier for automated assembly equipment to handle, reducing the risk of placement errors and rework costs.

5. Consider Equivalent Component Alternatives

Many components have functional equivalents from multiple manufacturers. By identifying acceptable alternates, you gain flexibility in sourcing and can choose options with better pricing or availability. Always verify compatibility and performance before switching.

We at Mu Star Group have helped thousands of customers optimize their costs by 20-30% through equivalent replacement components. If you have any needs, please contact us for assistance in providing this replacement solution.

6. Choose Standard Production Over Expedited

Rush orders come with premium pricing. Standard production timelines allow manufacturers to optimize their scheduling and material ordering, resulting in lower costs. Plan ahead to avoid expedited fees that can increase costs by 25-50%.

7. Consolidate Board Functions

Integrating multiple board functions into a single PCB can significantly reduce overall system costs. While the main board might become slightly more complex, you eliminate multiple connectors, housings, and assembly steps, leading to substantial savings.

8. Implement Long-term Demand Planning

Forecasting your production needs allows for better pricing negotiations. Manufacturers can offer volume discounts and secure better component pricing when they have visibility into your future requirements. Commit to longer-term contracts for additional savings.

Conclusion

Reducing PCBA manufacturing costs requires a balanced approach that considers design, materials, components, and production planning. By implementing these strategies, you can achieve significant cost savings while maintaining the quality and reliability of your products.

Remember that the most effective cost reduction comes from early planning and close collaboration with your manufacturing partner. Their expertise can help identify additional opportunities for optimization specific to your project.

Ready to optimize your PCBA costs? Contact us today for a personalized cost analysis and discover how our manufacturing expertise can help you achieve better value without compromising quality.